Skip to content

Track-TILLr-Manual-125-026-01

5 TT TRACK TILLr® Operator’s Manual

SAFETY INFORMATION

SAFETY INFORMATION

Farm Safety

How You Can Improve Farm Safety

Health and Safety Hazards on Farms

Health and Safety Hazards

Danger

Potential Effect or Injury

Prevention

Danger

Potential Effect or Injury

Prevention

1

Chemicals/Pesticides

Skin and respiratory injury or death

MSDS and proper Personal Protective Equipment. Review Manufacturers data sheets

2

Cold

Illness, Frostbite or death

Dress properly for the day.

3

Dust

Respiratory injury or explosive combinations

Be aware of your surroundings and activity

4

Electricity

Shock, burns, fire, death

Use a qualified professional for wiring dangerous electrical devices. Never overload a circuit. Replace damaged electrical devices or cords. Electrical tape will not insulate you from injury.

5

Grain bins, Silos

Entrapment, Suffocation, Explosion from formation of dangerous gases and poisoning.

Make sure the bin is properly ventilated and maintained. Never walk the grain.

6

Hand tools

Injury including cuts abrasions, electrocution, strains, sprains and death

Make sure you hand tools are in good condition. Never leave a damaged tooling accessible for someone

else to use.

7

Highway traffic

Collisions resulting in injury or death

Follow regulations, stay alert. Avoid alcohol and use of communication devices while driving.

8

Lifting & lifting devices

Back injury, sprains, strains. Falling material resulting in being struck or crushed by heavy material

Use proper lifting technique. Get help when the load is too heavy. Inspect chains, straps or cables routinely

to make sure they are in good condition.

9

Livestock handling

Serious injury or death resulting from being pinned struck or trampled.

Always make sure you have adequate room and an escape route.

10

Machinery/Equipment

Cuts, abrasions, amputations, death.

Thoroughly read and understand your Owners Equipment Manual. Never operate the equipment without

guards in place. Make sure the equipment can not be energized or otherwise put into operation while you

are working on it.

11

Manure pits

Explosion from formation of dangerous gases. Suffocation. Poisoning.

Proper maintenance.

12

Mud

Sprains, strains, entrapment and suffocation. Eye injury and skin irritation.

Proper Personal Protective Equipment. In some conditions a “Spotter” may be needed.

13

Noise

Hearing damage

Personal Protective Equipment.

14

Ponds

Drowning

Wear a life preserver and make sure help is readily available.

15

Slips/Trips/Falls

Sprains, strains, back and neck injury, bone breaks or death

Keep work area free from clutter and organized. If working on anything elevated make sure you have

appropriate guarding and/or fall protection such as a harness and lanyard.

16

Sun/Heat

Sun burn, Heat Stroke, shock, death

Use common sense on excessively hot days, use sun screen, wear a hat and stay hydrated.

17

Toxic gases

Skin and respiratory injury or death. Explosion.

MSDS and proper Personal Protective Equipment. Review Manufacturers data sheets.

18

Tractors

Cuts, abrasions, amputations, death.

Thoroughly read and understand your Owners Equipment Manual. Never operate the equipment without

guards in place. Anti-roll over devices.

19

Wells

Electrocution, amputation, death.

Avoid contact with water while working on an electrical device. Always be sure the equipment can/will not

be energized during repair or maintenance. Make sure all guarding is in place.

20

Sever weather

Electrocution, “struck by” injuries, death

Move to a safe place. Lightening, hail and tornadoes are unpredictable.

There are no rows in this table

High Risk Factors on Farms

The Benefits of Improved Safety and Health Practices

FOR YOUR PROTECTION

EQUIPMENT SAFETY GUIDELINES

SAFETY ALERT SYMBOL

Hazard control and accident prevention are dependent upon the safety awareness and proper training of personnel involved in the operation of this implement.

BE AWARE OF SIGNAL WORDS

DANGER

DANGER indicates a hazardous situation that, if not avoided, will result in death or serious injury. DANGER is limited to extreme situations, typically for machine components which for functional purposes, cannot be guarded.

WARNING

WARNING indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. WARNING includes hazards that are exposed when safety guards are removed. Warning may also be used to alert against unsafe practices.

CAUTION

CAUTION indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. CAUTION may also be used to alert against unsafe practices.

SHUTDOWN AND STORAGE

SAFE TRANSPORT

WARNING AND SAFETY LIGHTS

SAFE OPERATION

Safe Operation Guidelines

Icon

Guideline

Description

Icon

Guideline

Description

1

READ AND UNDERSTAND THE ENTIRE CONTENT OF THIS MANUAL BEFORE OPERATING OR SERVICING IMPLEMENT.

Implement is to be operated by qualified personnel only. Never let children operate

implement. A complete understanding of safety precautions, operation, and maintenance

is mandatory before implement use.

2

AVOID ELECTROCUTION.

Be aware of overhead power lines. Contact or close proximity to power lines can result in injury or death. Use extreme care when operating implement near power lines.

3

AVOID ROLLOVER.

Do not fold or unfold implement and avoid sharp turns when on a hillside, as shift of weight could cause rollover. Operate implement at a safe distance from terrain irregularities and other obstructions that could cause rollover.

4

AVOID CRUSHING.

Make sure all personnel are clear of implement at all times implement is in motion. Be aware of obstructions above, below, and around implement when in operation or transport. Injury or death can result from being struck by the implement.

5

NEVER ALLOW RIDERS ON TRACTOR OR IMPLEMENT.

Riders hinder operator visibility and can be thrown from the implement and/or be struck by foreign objects resulting in injury or death.

6

PRACTICE SAFE MAINTENANCE

Proper maintenance is your responsibility. Maintenance neglect and/or poor maintenance practices can result in injury or death. Always use the proper tools to maintain implement.

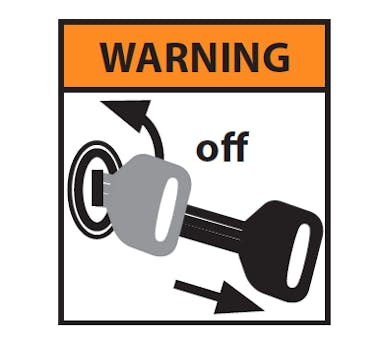

AVOID CRUSHING. Make sure all personnel are clear of the implement. Lower implement to the ground, place tractor in park, turn off engine, and remove key.

7

USE BAR STANDS AND CYLINDER STOPS TO SUPPORT THE IMPLEMENT.

Store implement on a clean, dry, and level surface. An uneven surface could cause implement to shift or fall, resulting in injury or death, as well as implement damage. Securely support all implement components that must be raised. Store implement away from human activity.

8

AVOID ENTANGLEMENT.

Never lubricate or service implement in motion. Keep away from power driven parts when in motion. Disengage power sources prior to maintaining implement. Injury or death can result from contact with power driven parts when in motion.

9

AVOID CRUSHING.

Do not stand between the tractor and implement when connecting or disconnecting implement. Injury or death can result from being trapped between the tractor and implement.

10

AVOID PRESSURIZED HYDRAULIC FLUID.

Escaping pressurized hydraulic fluid can penetrate skin, resulting in injury or death. Relieve hydraulic system pressure before connecting or disconnecting tractor. Use cardboard or wood, NOT BODY PARTS, to check for suspected hydraulic leaks. Wear protective gloves and safety glasses or goggles when working with hydraulic systems. If an accident occurs, see a doctor immediately for proper treatment.

11

AVOID EXHAUST FUMES.

Never operate a combustion engine in an enclosed area. Make sure there is adequate ventilation. Exhaust fumes can cause asphyxiation.

12

SERVICE TIRES SAFELY.

Tire and rim separation can result in serious injury or death. Do not over inflate tires. Only mount or dismount tires if you possess the proper equipment, otherwise contact a trained professional. Always maintain correct tire pressure. Inspect tires and wheels daily. Do not operate tires with inadequate pressure, cuts, visible damage, or missing hardware.

13

AVOID SHARP EDGES.

Be extremely careful working around unshielded sharp edges. Injury may result from contact with sharp edges.

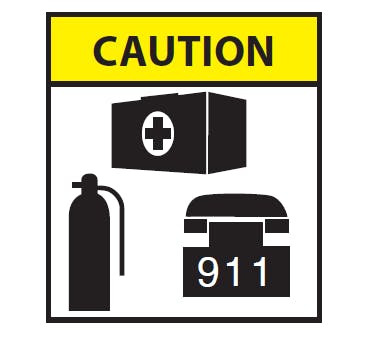

14

PREPARE FOR EMERGENCIES

15

AVOID ANHYDROUS AMMONIA - NH3

LIQUID FERTILIZER

ANHYDROUS AMMONIA (NH3) AND LIQUID FERTILIZER APPEARS HARMLESS. DIRECT EXPOSURE TO NH3 OR LIQUID FERTILIZER IS EXTREMELY DANGEROUS AND CAN RESULT IN INJURY AND/OR DEATH.

16

SAFETY DECALS

Safety decals promote awareness and knowledge concerning safe operation and maintenance of the implement.

Carefully READ ALL SAFETY DECALS in this manual as well as on the implement.

Keep implement clean so decals are easily visible. Keep all decals in good and legible condition. Immediately replace damaged and/or missing decals. Replacement decals are available from your Orthman dealer.

To install decals: Thoroughly clean area where decal is to be placed and attach decal void of

bubbles. Refer to this safety information section for proper decal placement.

There are no rows in this table

SAFETY DECALS

5 TT Track-TILLr Decals

Item

Decal number

Decal

Location

Decal image

Item

Decal number

Decal

Location

Decal image

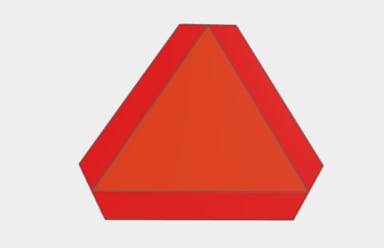

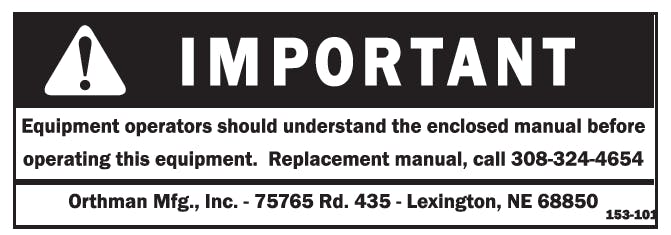

1

1

153-173

Red retro-reflective

Rear of machine, end of disc gang frame

2

2

153-478

TRACK TILLr logo

Rear of machine

3

3

153-172

Amber retro-reflective

Front of machine, end of disc gang frame

4

4

153-173

Red retro-reflective

SMV sign

5

5

153-430

Orthman logo

Both sides of machine

6

6

153-101

Manual enclosure

7

7

153-469

5 TT logo

8

8

153-011

Orthman serial tag

3-Point center mast plates

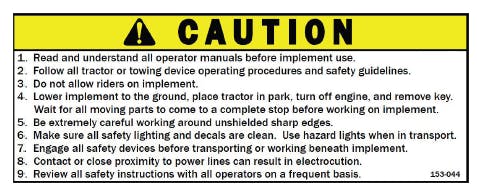

9

9

153-044

Caution label

End of disc-gang frame

There are no rows in this table

Want to print your doc?

This is not the way.

This is not the way.

Try clicking the ⋯ next to your doc name or using a keyboard shortcut (

CtrlP

) instead.