Skip to content

Track-TILLr-Manual-125-026-01

5 TT TRACK TILLr® Operator’s Manual

FIELD SETTINGS

FIELD SETTINGS

Field Operation

Transport Position

Field Position

Implement Alignment

Field Adjustments

Guide Wheel Depth -

Due to shipping requirements, the guide wheel’s factory setting is NOT set for operation.

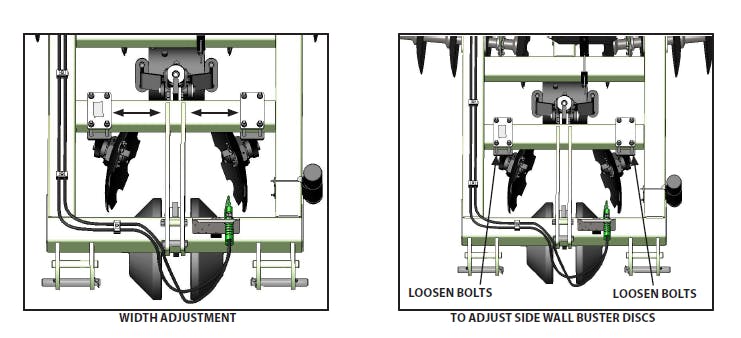

Side Wall Buster Disc Width

Track Packer Depth and Down Pressure

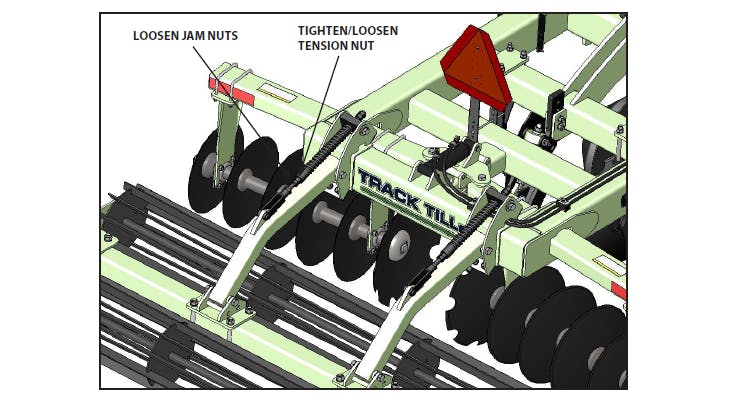

Rear Disc Gang Angle

Rolling Baskets Down Pressure

Load content from app.zea.live?

Loading external content may reveal information to 3rd parties. Learn more

Want to print your doc?

This is not the way.

This is not the way.

Try clicking the ⋯ next to your doc name or using a keyboard shortcut (

CtrlP

) instead.